Our technology converts plastics from a waste material that is otherwise difficult to recycle, to valuable hydrogen and syngas products

The technology comprises a multi-stage thermal process, converting plastics at temperature, in a sealed, oxygen free environment.

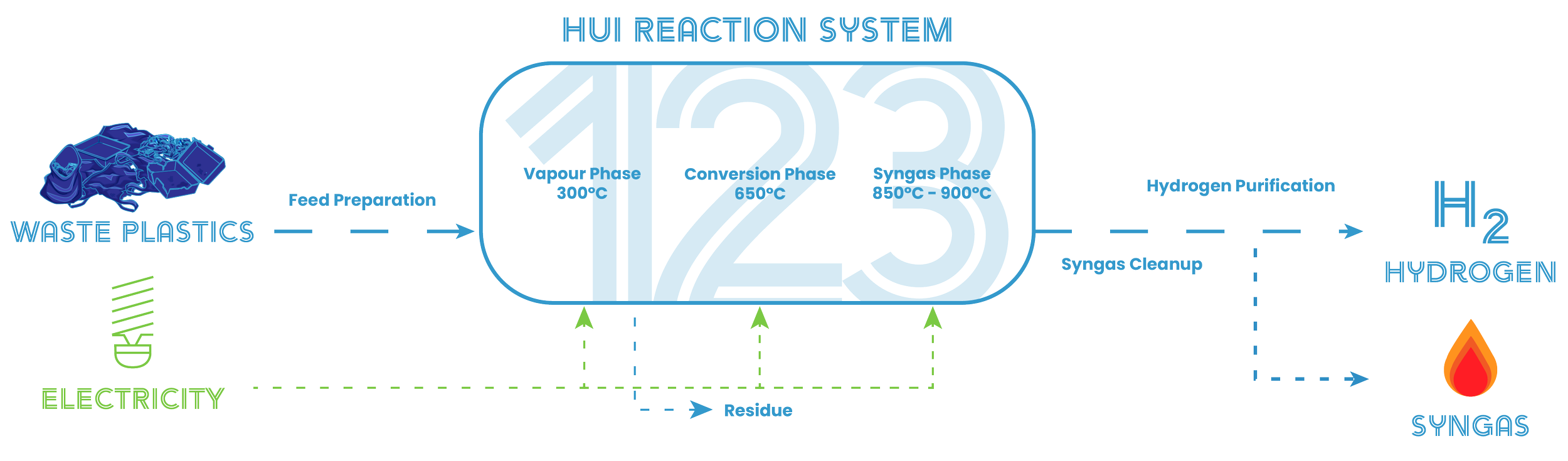

Prior to entering the reactor system, the received plastic feedstock is shredded to size and dried. No sorting or cleaning is required.

In the first stage reactor, the plastics are heated to around 300°C, and undergo transition to vapour phase, with any solid contaminants that may be present in the feedstock separating out. This residual solid material is cooled and removed; this removal takes place such that no reactor gases escape.

Further heating to around 650°C takes place in the second stage reactor, where the material is converted to a mixture of gases.

The third stage reactor operates at 850 to 900°C, where the complex mixture of gases break down to a synthetic gas known as “syngas”, with the major components of methane, hydrogen and carbon oxides. The conditions within the reactor system are oxygen free, and therefore no combustion or “burning” takes place, and there are no emissions of the gas mixture to atmosphere. By using Green Electricity to heat the reactors, no CO2 is emitted in powering the reactors.

The resulting syngas is cooled, recovering the energy, and passes to the gas cleanup section, where trace components resulting mainly from contaminants in the waste plastics are removed. The hydrogen is extracted from the syngas, and purified to export grade (99.999%) using pressure swing technology.

The remaining syngas can be exported as a base chemical, or used to generate heat or power, depending on the specific application.

What are the Benefits?

Efficiency

High conversion efficiency, syngas purity and gross generating capacity efficiency

Versatility

Capable of dealing with mixed unrecyclable plastic

Green

End of waste syngas produces fewer pollutants than high energy gas – and meets all legal requirements

Clean

All hazardous by-products extracted safely and disposed of appropriately

Sustainable

Enables low carbon, low cost distributed hydrogen for future use in road vehicles

Profitable

Far greater returns from valorising waste plastic